Fujairah seawater reverse osmosis desalination plant (United Arab Emirates)

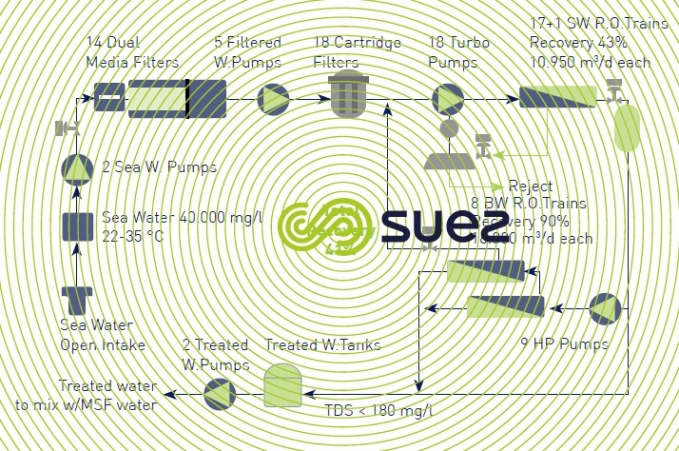

The Fujairah’s SWRO plant is part of the large complex proposed by Doosan to the UWEC (Union Water & Electricity Company) to fulfill its need of 500 MW (net output on the electrical grid) and 100 MIGD water production mainly used for irrigation of the Al-Ayn area due to severe depletion of the local aquifers.

The main originality of this proposal was to choose in 2002 a hybrid plant for the water production i.e. 62.5 MIGD from 5 MSF units coupled with the power plant and 37.5 MIGD from seawater reverse osmosis.

Equipment delivery, plant erection and commissioning were achieved within a very tight schedule of 24 months. A 6 months pilot testing optimizes the pre-treatment stage and the chemical regime in relation to the seawater quality.

pretreatment

- A dosing system able to dose up H2SO4, FeCl3 (pure) and polymer to be mixed with the seawater in two static mixers and two coagulation tanks.

- 2 lines of 7 open dual media filters (Mediazur) fed by gravity and handling up to 1,500 m3/h of seawater.

- 2 lines of 9 cartridge filters each with 360 cartridges (5 microns).

reverse osmosis

To achieve a salinity lower than 180 mg/l, the RO design incorporates a double pass system :

- 1st pass: 17 + 1 trains, each one with 136 PV x 7 elements SWC3 Hydranautics high rejection modules with a recovery rate of 43 %,

- 2nd pass: 8 trains, each one with 70 PV x 7 elements >recovery rate of 90 %.

A pressure regulation is provided to compensate automatically for the change in membrane permeability and temperature in such a way to minimize the energy requirement of the whole system.

treatment line

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later