Meistratzheim wastewater treatment plant (France)

A model plant in recovering potential energy from sludge.

With a 240,500 population-equivalent capacity, this plant, built by SUEZ, treats the wastewater of 11 towns located in the Terres de Saint Odile area (i.e. 24,000 inhabitants) and the effluent of local sauerkraut manufacturing plants (i.e. the equivalent wastewater of 140,000 in habitants at peak flow).

Thanks to its layout and the cutting edge technologies deployed, the plant consumes minimum energy, and even go as far as producing a portion of the energy it requires for operation.

Indeed, sauerkraut juices and fats recovered during treatment and the sludge resulting from treatment, separately produce biogas. Through the anaerobic digestion of the sauerkraut juices or through digestion of the sludge and grease, bacterial populations coming into contact with these products, absorb and digest their compounds.

Thanks to cogeneration, the biogas, produced by these two phenomena, may be used to produce the heat required by the anaerobic digestion tank, the digester, the double-level dryer as well as for heating the premises and domestic water. Excess biogas may be transformed into electricity which is sold to the EDF network.

sludge treatment :

Sludge is a wastewater treatment plant by-product. It can contain more than 95% water as well as suspended solids and other residues. This volume of water needs to be reduced in order to make removing sludge by truck easier and to recover it correctly. Treating the plant's sludge also leads to the production of energy.

thickening :

An initial treatment uses the drip technique which allows a large part of the water in the sludge to be recovered. Nevertheless, following this stage, the volume of sludge still remains significantly high.

digestion :

Taking place in a Digeco digester along the same principal as anaerobic digestion but with a different bacterial population, the anaerobic digestion of sludge removes a significant quantity of organic matter. Anaerobic digestion also has the advantage of producing biogas which can be recovered as energy. A flexible gas tank, located above the digester, stores the biogas produced.

centrifuge :

In order to continue to remove the water, sludge is centrifuged.

drying :

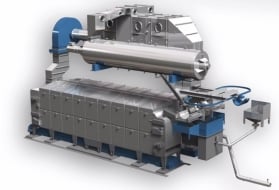

To finish off the treatment, sludge is dried through the stage EVAPORISTM. Innovative, it operates on two levels. On the first level, sludge is spread into think layers and comes into contact with heat produced from oil at 165°C. The sludge is then transformed into "spaghetti" which, for the last time, is dried by warm air. The output sludge is in the form of dry granules. The granules can be either recovered in agriculture or in incineration processes.

sludge treatment process :

- Fenced thickening of primary sludge;

- Mechanical thickening of secondary sludge;

- Anaerobic digestion of mixed sludge;

- Centrifuge dewatering of digested sludge:

- Thermal drying of dewatered sludge the EVAPORIS LE stage.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later