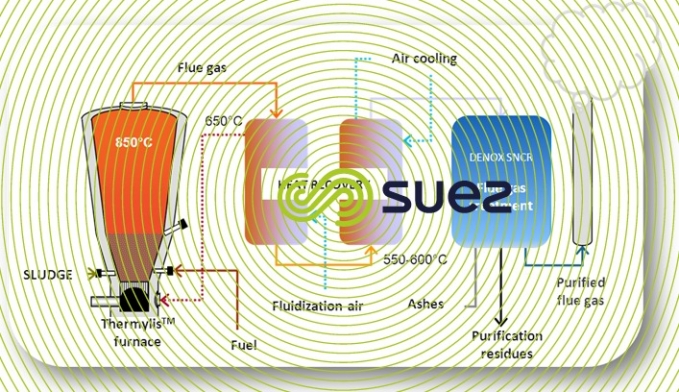

sludge incineration – Thermylis™

The ThermylisTM transforms sludge into a mineral product that is not harmful and that can be recycled. It is preferentially fed with dewatered sludge (dryness between 15 to 40%) from urban or industrial wastewater. The ThermylisTM is particularly suited to wastewater treatment plant with capacity greater than 100,000 PE.

key figures

- Automated operation 24h/24

- Final reduction of sludge volume between 7 to 10% of dewatered sludge volume

among references

- Mill Creek facility (Cincinnati, Ohio, USA) 3*90 t.DS per day

- Lakeview (Canada) 4*100 t.DS/day

- Limited nuisances: optimal quality of combustion allows the respect of standards

- Economic : hot wind box limiting energetic costs

- Flexible : possible intermittent operation

- Reliable : construction built since 1985 are still in operation

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later