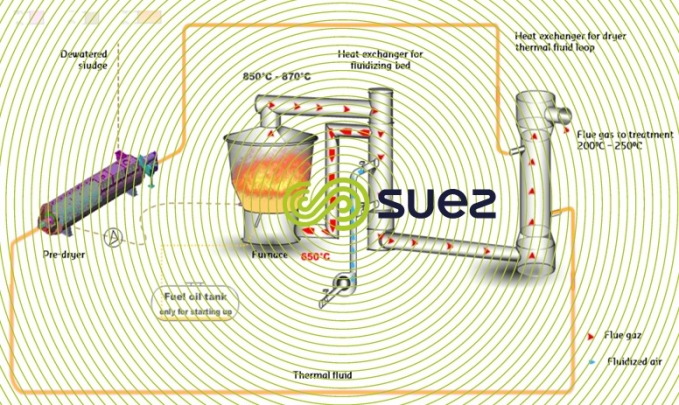

stage sludge incineration autothermal: pre-drying + incineration – Thermylis™ 2S

The ThermylisTM 2S, a sustainable technology based on energy recovery, provides one of the most efficient, the most economical environmentally-friendly means to reduce sludge volume. A combination of an incinerator and a sludge dryer supporting system’s energy self-sufficiency.

key figures

- Final reduction of sludge volume between 7 to 10% of dewatered sludge volume

- Automated operation 24h/24

- Up to 0 fossil fuel consumption

among references

- Kielce (Poland) 300,000 PE

- Gdansk (Poland) 800,000 PE

- Valenton (France) 1*50 tDS/day

- Shenzhen (China) 2*80 tDS/day

- Near-zero fuel consumption (fuel, gas) due to recovered energy

- Sludge volume reduction reduces transport and landfill costs

- Reduction of greenhouse gas emissions

- Complete elimination of pathogens and hormonal molecules thus strengthening health and safety

- Maximal combustion yield

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later