degremont® compact units (UCD)

Reading time:Some of the wastewater treatment technologies previously presented in this chapter have been integrated into a metallic standard format, quick to implement: the degremont® compact unit (UCD®). Its compactness also easies transportation (most often in shipping containers).

The UCD® products available for urban wastewater treatment can treat between 15 and 5,000 m3/d of effluents. These products can adapt to any discharge constraints (carbon, nitrogen and phosphorous treatment, reuse, disinfection…).

The processes are implemented as follows:

- UCD® ASC (formerly known as Minibloc) : Activated Sludge Clarifier, activated sludge via extended aeration;

- UCD® SBR : Sequenced Batch Reactor, Cyclor process;

- UCD® MBBR : Moving Bed Biofilm Reactor, MeteorTMprocess;

- UCD® MBR : Membrane Bio Reactor, Ultragreen and Ultrafor processes.

Electromechanical equipment is integrated from the design phase and is assembled on metallic skids in a workshop.

The modular nature of the available units allows the implementation of several of them in order to reach the final treatment capacity.

In addition to the core process, various options are proposed: lifting pumping station, buffer tank, tertiary treatment, sludge treatment and/or storage.

UCD® ASC (formerly known as Minibloc)

The UCD® ASC offers a range of 5 models with a capacity of between 15 and 75 m3/d. Units can be assembled in parallel.

The various UCD® ASC models include the following elements:

- a pre-treatment screening;

- an aeration tank for activated sludge with air delivery pipes and medium-sized / large-sized bubble diffusers;

- a settling zone;

- a sludge storage compartment;

- an electric protection and control cabinet.

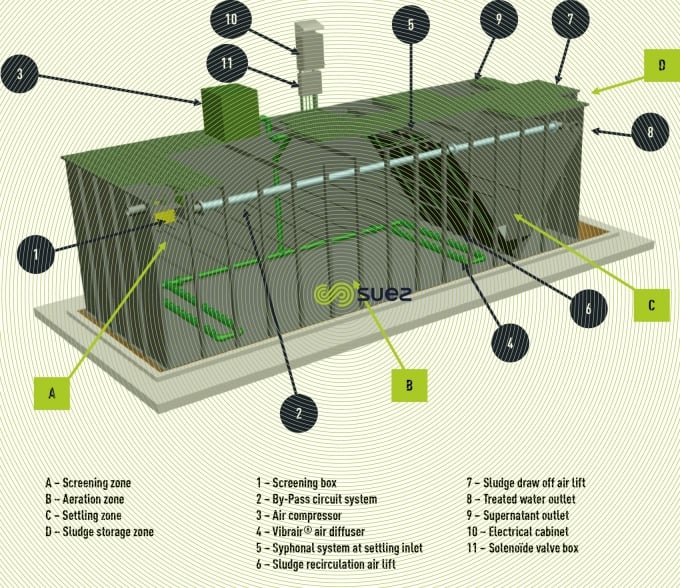

UCD®SBR

The UCD® SBR is a Sequenced Biological batch Reactor used in the Cyclor® process.

The treatment process includes in a single tank the following steps: filling, biological treatment, settling and discharge.

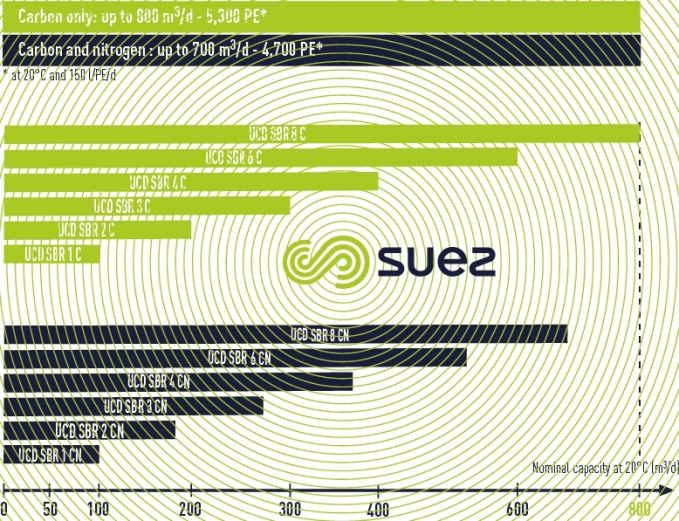

The UCD® SBR product is available in various configurations involving 1 to 8 cells corresponding to capacities of between 100 and 800 m3/d (with carbon treatment only, at 20°C and for pollutants concentrations complying with European standards).

The various UCD® SBR models include the following elements:

- a pre-fabricated lifting pumping station (upstream of the treatment unit);

- a buffer tank to lope the hydraulic peaks during dry weather;

- an automatic rotary screen equipped with a compactor;

- a metallic bio-reactor equipped with a floating weir to drain treated water;

- an aeration system at the bottom of the tank (air delivery pipe, medium-sized / large-sized Vibrair® bubble diffusers and blower);

- a settled sludge collector;

- a sludge storage / thickener tank equipped with static thickening grids and mixers;

- an electrical cabinet ensuring the automatic operation of the facility.

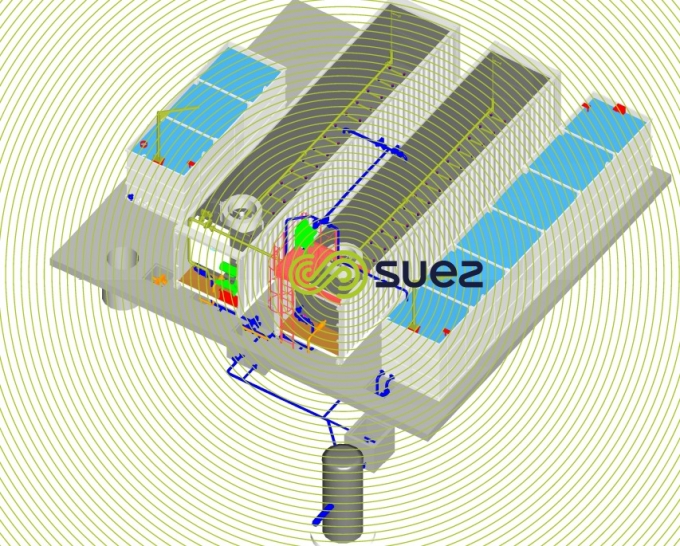

UCD® MBBR

The UCD® MBBR is a mixed growth biological as implemented in the MeteorTM process.

The MBBR process uses fluidized growth fixed on mobile media and is associated with a separation stage (lamellar clarification or mechanical filtration).

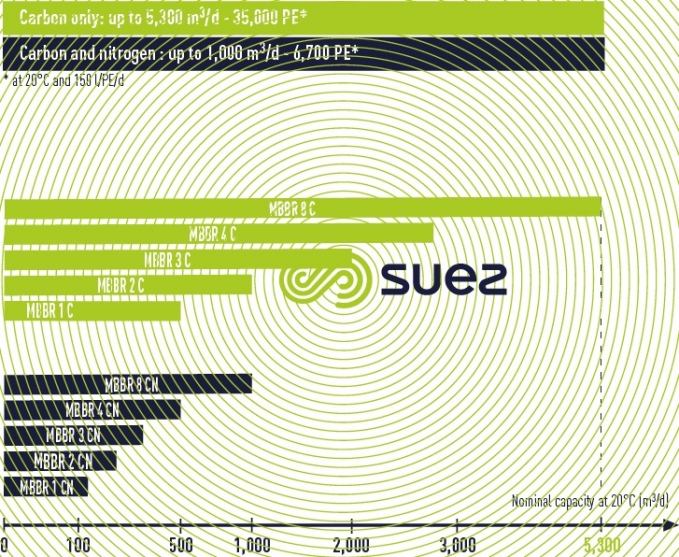

The UCD® MBBR is available in several models of between 1 and 8 cells for a capacity of between 660 and 5,300 m3/d (with carbon treatment only, at 20°C and for pollutants concentrations complying with European standards).

The various models of the UCD® MBBR are automated and include the following elements:

- an automatic rotary screen equipped with a compactor;

- a compact Primegreen® primary settling tank;

- a metallic aerated biological reactor of the MBBR type;

- biomass support media of the MeteorTM660 type and the associated retention grids;

- an air blowing system at the bottom of the tank (air delivery pipe, diffusers and blower) for biological aeration and the suspension of supports;

- a lamellar clarification or mechanical filtration tank (as an option, coagulant dosing depending on the project).

UCD®MBR

Designed for compact wastewater treatment plants which discharge into sensitive environment or for water reuse, the UCD® MBR range is based on the degremont® Membrane Bioreactor processes: Ultrafor (hollow fibre membranes) and Ultragreen (plate membranes).

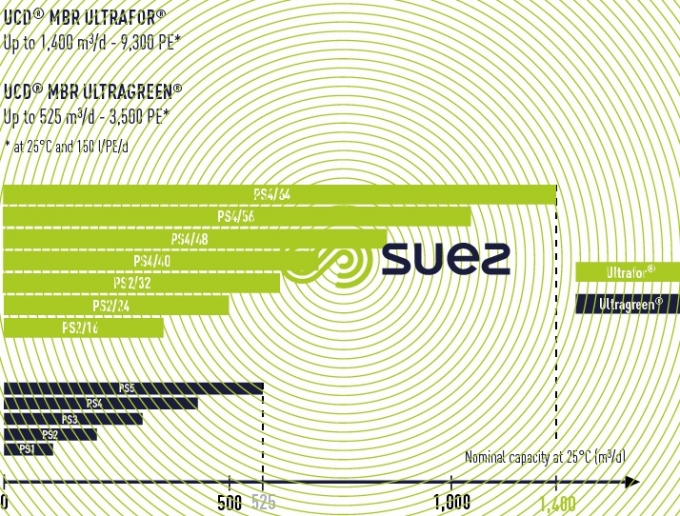

The UCD® MBR constitutes a range of standardised treatment solutions enabling the treatment of flows of up to 1,400 m3/d (at 25°C and for pollutant concentration complying with European standards).

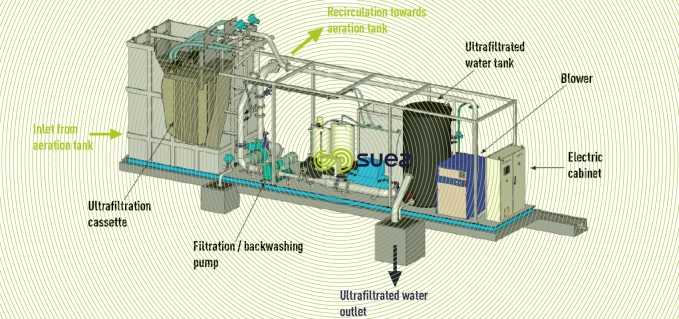

Membrane ultrafiltration is in this case organized as a “skid”, allowing a very quick implementation and minimizing the costs of road and maritime transport. Our range of ultrafiltration units is composed of 13 models with increasing membrane surfaces. These units are designed for a fully automatic operation thanks to their on-board electrical/control cabinet.

The various models of the UCD® MBR include the following elements:

- an automatic rotary screen fitted with a compactor;

- a metallic aerated biological bioreactor made from glass-lined bolted steel, with its medium-sized / large-sized bubble diffuser aeration systems;

- an ultrafiltration skid including:

- a filtration tank in which membranes are immersed;

- reagent storage and dosing units for membrane cleaning;

- electromechanical pumps and equipment;

- the electric cabinet;

- an air blowing system at the bottom of the tank (feed pipes, diffusers and blower) in order to unclog membranes.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later