filters backwashed with air and water simultaneously

Reading time:These filters have one single, homogenous layer and are backwashed simultaneously by air and water.

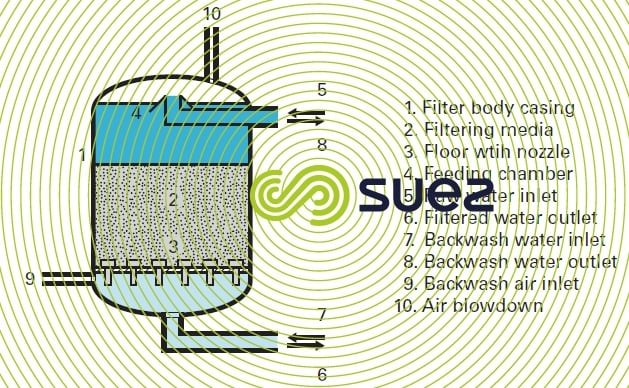

The filter bed is homogenous throughout its depth and supported on a metal floor or on a collector embedded into the support layer. Rings are fixed on this layer and the nozzles are screwed onto these rings. These filters are usually loaded with sand, occasionally with anthracite.

This type of filter usually has the following properties :

- sand having a granulometry (E.S.): 0.55 to 1.35 mm;

- air flow rate: 55 m3·h–1·m–2;

- water flow rate during the air scour: 5 to 7 m3·h–1·m–2;

- rinsing water flow rate: 15 to 25 m3·h–1·m–2;*

- head loss at the end of the cycle: 0.2 to 1.5 bar.

Layer depth will mainly be defined by the filtration rate and by the extent of the load of material that has to be screened out. Filtration rates usually range from 4 to 20 m · h–1. In special cases, this filter can be used with 1 to 2 m deep layers and with sand granulometry of between 0.65 and 2 mm. The following rates can then be achieved:

- 20 to 40 m · h–1 for coarse pressure filtration of water carrying oxides (see the steel industry);

- 25 to 40 m · h–1 for fine filtration applied to deep seawater.

These filters are ideally suited for use with batteries of large diameter units and have significant advantages: totally safe and simple operation; low instantaneous backwash water flow rate and, consequently, minimum wash water consumption.

possible configurations:

FV2B filters (figure 7)

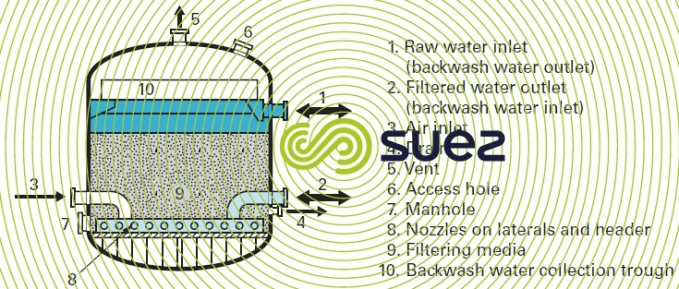

FH filters (type FH-S)

One or two-troughs horizontal filters with a specific arrangement for collecting backwash water (figure 8) :

- layer depth of approximately one metre;

- 2.5 to 4 m diameters, up to 16 metres long;

- applications: filtration of large industrial water throughputs (carbonate removal, rolling mills, seawater).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later