treatment systems

Reading time:SUEZ has designed two systems that are cost-effective for plant discharging approximately 8 hydrojets per day (i.e. approximately 5 t · d–1 of pulp) to which has to be added the grit produced by the plant's grit removers.

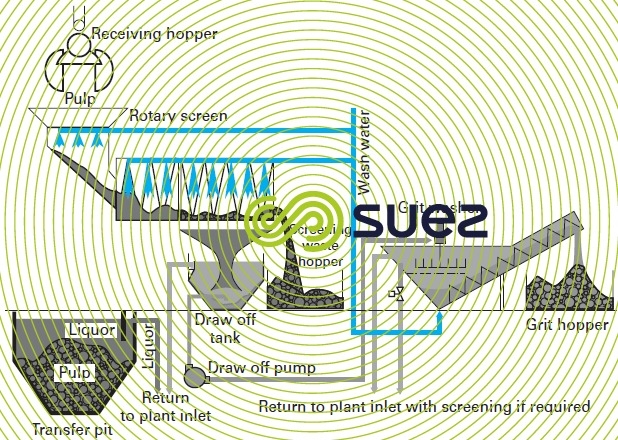

arenis low flow rate system

This system comprises (figure 9):

- a clamshell bucket;

- a rotary screen;

- a grit washer classifier.

Overdesigned, the wash stage is carried out in a rotary screen and, therefore, does not include a hydrocyclone but does enable us to ensure OM levels <5%.

A storage period of at least 1 month must then apply.

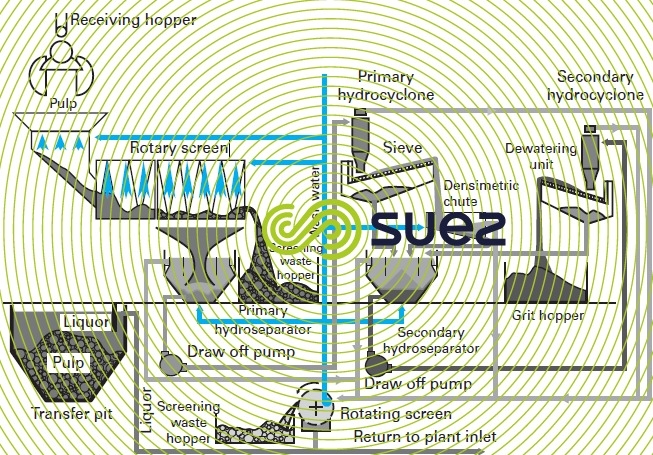

arenis high flow rate system

This system comprises (figure 10):

- 1 clamshell bucket;

- 1 rotary screen;

- 2 hydroseparators;

- 2 hydrocyclones;

- 1 densimetric channel:

- 1 vibrating dewatering unit;

- 1 rotating strainer on the overflows.

This system enables us to guarantee 3% residual OM; however, we still recommend that the heap is allowed to ripen.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later