agri-food industries

Reading time:breweries and carbonated drink manufacturing

The main water treatments encountered include :

- carbonate removal from water used to produce beer and from water used to dilute concentrates (carbonated beverages);

- iron removal, manganese removal, nitrate removal … when using well water polluted by these elements;

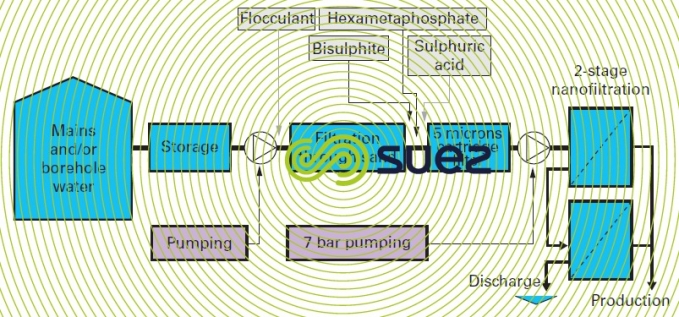

- if necessary, brewery water partial demineralization using nanofiltration or reverse osmosis in order to obtain standardized water that also enjoys irreproachable bacteriological and organoleptic qualities (figure 10).

mineral water and spring water

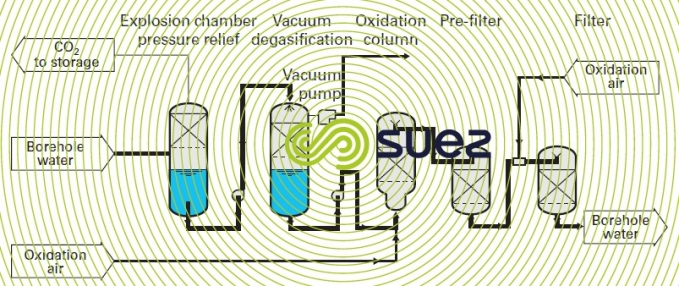

Mineral water is often rich in iron and manganese that have to be eliminated before bottling. This water also occasionally contains a little ammonia. After vacuum de-aerating if necessary (case of naturally carbonated water), iron is removed from the water by air oxidation and the water is then filtered through sand. Ammonia is converted into nitrate by nitrification through nitrifying filters.

With spring and table water, ozone can be used for iron and manganese removal (figure 11).

starch plants – glucose plants

Major consumers of water, they are often supplied from surface water that requires advanced potabilisation treatment in order to remove pesticides and micro-pollutants.

Conventional treatments include :

- clarification or carbonate removal using lime;

- ozonation;

- filtration through sand;

- treatment through activated carbon (for removing pesticides);

- final chlorination;

- demineralization using ion exchanges for boiler feed water.

A more modern system that does not create pollution (no saline discharge) will include :

- river water bar screening;

- clarification membrane to produce soaking water and for RO pre-treatment;

- reverse osmosis for producing boiler feed water.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later