organic matter destruction using the wet oxidation method

Reading time:There is a group of oxidation processes used on sludge organic matter that overcome traditional heat problems and, therefore, the lengthy flue gas treatment process. This series of processes is grouped under the heading of wet oxidation. In effect, this system "incinerates" liquid sludge "without any flames".

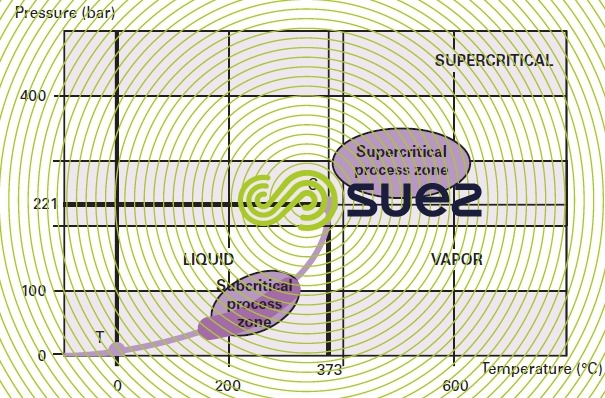

These processes differ in terms of the location of their operating zone (temperature-pressure pair) in relation to the critical point for water (221 bar, 373 °C) (figure 45).

Below the critical point: subcritical wet oxidation was developed during the 1950's for processing black liquors and sludge. In this two-phase process, oxygen dissolved in the liquid phase reacts with organic compounds. Applied to sludge, the pressures used range from 40 to 100 bar.

Beyond the critical point: supercritical wet oxidation uses the fact that organic component and gas (oxygen) solubility can be regarded as infinite. Everything takes place as if the system was a single phase system, i.e. without oxygen transfer stage. Consequently, very high levels of destruction can be achieved (>99%) for very short contact times (approximately one minute). However, the development of this technique does have problems that are primarily associated with restrictions created by both pressure conditions and by problems concerning mineral salt precipitation, mineral salts being almost insoluble. Precipitation also creates corrosion problems, particularly when chlorinated compounds are present. At present, in the sludge sector, the supercritical process is still at the experimental stage. Therefore, we shall only discuss the subcritical process version that we have developed under the Mineralis designation.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later