principle and conditions governing its use

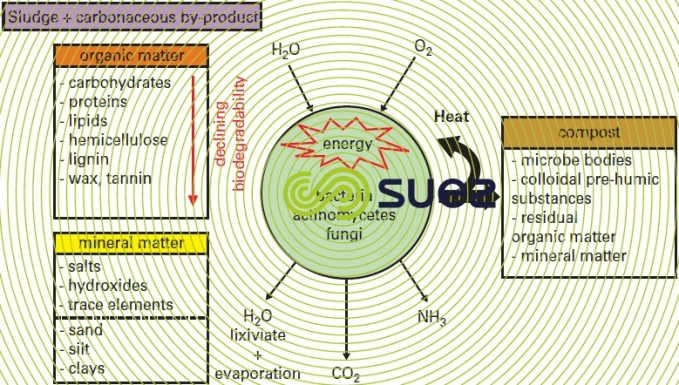

Reading time:Composting is controlled fermentation that converts organic matter aerobically and produces stable humic and pre-humic compounds (figure 1). Aeration will only be effective if the medium is air-permeable. Dewatered sludge often has a low porosity; a bulking agent has to be added, usually in the form of a carbonaceous support (20% of the mixture at least must be formed by voids).

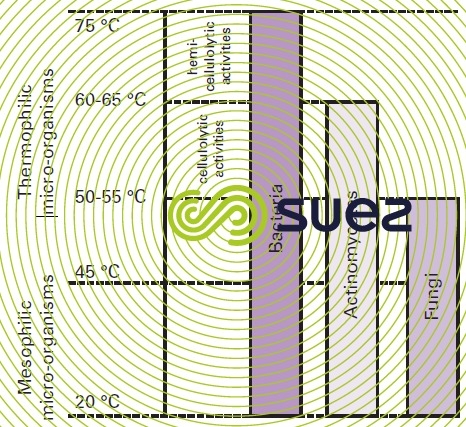

This degradation caused by various micro-organisms (figure 2) is accompanied by a rise in temperature which can exceed 70°C: this will destroy pathogenic germs and reduce product humidity (evaporation).

Composting should be applied preferably to fresh sludge (rich in OM and nitrogen) but can also be used on digested or stabilised aerobic sludge.

The following medium conditions are specific to composting:

- micro-flora exists in its natural state in sludge or in the air and, therefore, no seeding is necessary;

- the pH is not a fundamental parameter for satisfactory composting because it will adjust very quickly between 6.5 and 8 (acidification at the start of composting and then alkalinisation through the formation of ammonia and the removal of CO2 through aeration); even sludge produced by the physical-chemical treatment of UWW can be composted.

dry solids contents of the initial mixture and of the final compost

Aeration provides oxygen for biological oxidation and also eliminates the water vapor and carbon dioxide given off by the compost mass. The better the climactic conditions, the more effective the dewatering using air circulation.

The optimum humidity level of the initial mixture will range from 55 to 65 % (35 to 45 % of dry solids contents).

The higher the biodegradable organic matter content (BOM), the better the exothermic reactions created by its breakdown will allow water to evaporate and, therefore, the compost to dry out. In practice, it would seem that, in order to guarantee a compost dry solids content of better than 50 % after a three-week aeration cycle, the index I (I = kg of water per kg of BOM in the initial mixture) must be below 10.

Aiming for a high final compost dry solids content also calls for high energy consumptions (high volume of air to be injected). This consumption could represent more than 80 % of overall consumption.

nutritional balance

The C/N ratio governs all microbial dynamics. In fact, the form taken by the carbon content in the sludge to be treated and the by-product is an essential factor :

- carbon that is not easily assimilated by the micro-flora will inhibit degradation kinetics and the conversion of the sludge’s organic matter; in this case, nitrogen, often present in excess, will be discharged as ammonia (a compound most frequently found in the gas phase generated by the process);

- if carbon can be easily assimilated, an additional amount of nitrogen may be necessary to avoid restricting microbial kinetics (case of certain IWW sludges).

Carbon availability in wastewater sludge will vary with the sludge type concerned: carbon availability will be higher in fresh sludge than in digested sludge, higher in primary sludge than in biological sludge.

The by-products often used on industrial composting platforms (sawdust, wood shavings, wood chips, ground up pallets, bark) are low in easily assimilated carbon (cellulose and lignin are not easily biodegradable). When included in a mixture, their main role will be to produce bulking and to make the compost easy to handle. Conversely, crushed green waste usually contains more easily biodegradable carbonaceous compounds such as proteins and hemicelluloses.

selecting the carbonaceous support

The support plays several roles :

- as a bulking agent, it creates voids within the mixture, allowing air through;

- as a structuring agent, it endows the mixture with a mechanical stability that makes it easy to handle;

- as a carbonaceous soil improver, it contributes carbon (if it can be assimilated) that will redress the C/N balance;

- texturing agent: the carbonaceous support acts like a sponge, absorbing a proportion of the humidity found in the sludge and improving the latter’s structure.

The entire range of organic supports is used: sawdust (very widespread) and also crushed green plant waste, wood chips or shavings, crushed bark, chopped straw, grape must, flax shives, maize husks…

In order to reduce carbonaceous support purchase costs, the following are used with increasing frequency:

- recycled, partially dewatered compost;

- coarse supports are sieved and re-used (shavings, bark…).

The initial humidity of dewatered sludge defines the quantities of support to be added: for a 20 % dry solids content cake, approximately three volumes of support (fresh, recycled or composted product) will be required for each volume of sludge.

maturation

After any composting (more or less prolonged depending on the technique used), before the compost can be used for agricultural purposes, the mixture has to be stabilised by undergoing a one to three-month maturation period (usually in windrows) during which the product has to be turned over at regular intervals. Both the C/N ratio and the pH will drop and the nitrogen will be nitrified. The humification phenomenon commences during that period.

main sludge composting processes

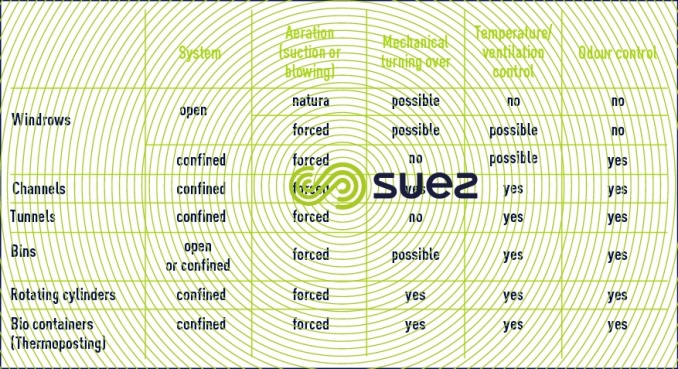

Suitable machines are used to turn the compost heap over; this operation aerates and loosens the heap, redistributing the voids. During the active phase of composting, mechanical turning ensures that sanitising temperatures are applied to the entire mass (see EPA regulation in sludge end uses).

When so-called confined systems are used, biological processes can be regulated by, for instance, cross-linking ventilation to an insufficient temperature or oxygen level.

The application of stringent guarantees with regard to olfactory emissions requires the installation of controlled and forced ventilation composting systems where the gas phase can easily be collected and routed to a biological or chemical odour control unit.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later