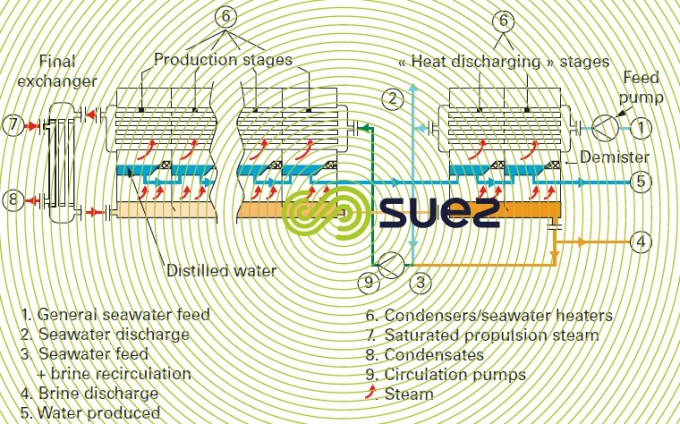

multi-stage flash distillation with recirculation

Reading time:In this unit, a circulation pump (9) sends a counter current of seawater into a bundle of tubular condensers; this seawater heats up gradually by recovering condensation heat from each stage (6); live steam condensation provides final stage heating through the last exchanger. Once the seawater has reached a temperature of approximately 110 °C (max. temperature), this temperature drops from one cell to the next, by undergoing a series of pressure releases (each cell or stage working at a lower pressure than the previous one) thus releasing energy stored as vapor. When the vapor comes into contact with the cold outer surface of the bundle of condensers, the vapor transfers condensation energy towards the seawater that circulates inside the tubes and produces distilled water.

This technology has prevailed over several decades from the 60’s. Its main advantage is that it eliminates exchange surface areas at vaporisation, thus reducing the temperature drop from one cell to the next by 2 °C and allowing up to 30 cells to be installed in series and specific consumption levels of approximately 80 kcal·kg–1 of distilled water to be achieved, in the knowledge, however, that recirculation (9) and cooling (1) pumps alone will use between 2 and 3 kWh·m–3 of distilled water.

MSF technology allows us to produce units that each have a capacity of up to 78,000 m3 per day. All the large units are linked into power plants, using all or part of the steam extracted from these plants’ low pressure turbines (2 to 3 bar) (see also section desalination membrane application).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later