belt filter filtration: principle

Reading time:The filtration process always comprises the following stages:

- flocculation using polyelectrolytes, in short contact time flocculators, or sometimes in the pipeline;

- flocculated sludge drainage: the interstitial water released is drained through a filtering medium. This causes the sludge to thicken rapidly; in order to obtain the best performances, the sludge that reaches the end of the draining zone must be as concentrated as possible (a laminar roller is added for this):

- pressing the drained sludge: this sludge will be of sufficient consistency and will be trapped between two filter belts, wedge-shapping, gradually compressing the sludge. The «sandwich» formed is then rolled in succession around a perforated drum, then around rollers laid out in a staggedred formation, following a route that varies depending on the type of filter.

Dewatering effectiveness depends on the effective pressure Pe applied to the sludge sandwich and also on pressing time.

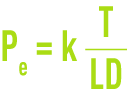

In a simplified form, pressure Pe or surface pressure, takes the following form:

where T: is the belt tensio,

L: is the belt width,

D: is the roller diameter,

Pe is therefore obtained by the belt tension round the rollers: Pe will increase as the roller diameter decreases. However, Pe remains moderate (0.3 to 1 bar) due to the limited mechanical strength of the filter belts and rollers.

Pressing time depends on the active pressing surface on the rollers and on unrolling speed.

Water is released as the sludge undergoes shear stress when it travels around the rollers. The water is discharged alternately, to one side and then to the other of the sludge «blanket».

In belt filters, pressing does not take place in an enclosed compartment: therefore, it is the sludge that, under the pressure it can tolerate as it travels around, provides lateral sealing; if this pressure is too high, the sludge layer cohesion is destroyed and there will be squeezing out, with partially dewatered sludge leaving the filtration area.

Pressure rates causing lateral squeezing out clearly depends on the physical structure of the drained sludge. Therefore, dry solids contents produced by belt filters will be lower than those achieved with sealed compartment filters (filter presses) where the pressure applied will only be limited by the filter's mechanical strength.

There are two ways of improving the dry solids content of the cake:

- the number of windings can be increased and the roller diameter reduced in the final filtration section (within the limits of the filter structure’s mechanical strength);

- external compression systems that are independent of belt tension can be used.

However, these additional devices can only be used on high-cohesion sludge such as fibrous sludge.In effect, more colloidal sludge would not be capable of withstanding this additional compression or would only produce a minimum extra dry solids content.

Classic belt filters are used to obtain easy-to-shovel sludge from most organic or hydroxide sludge.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later