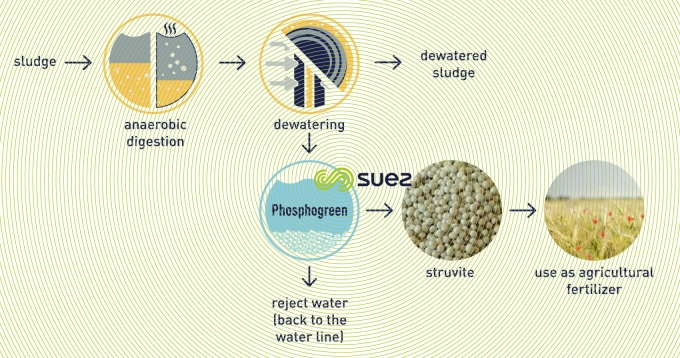

recycle phosphorus from effluent to produce a valuable fertilizer- Phosphogreen

Phosphorus is recovered from phosphorus-rich effluents. They are introduced into the Phosphogreen reactor where carbon dioxide is degased by air injection. The pH is measured and adjusted if necessary, by adding sodium hydroxide to optimize the reaction conditions.

The heart of the process consists in injecting magnesium chloride to obtain precipitation-crystallization of struvite. Struvite is then extracted at the bottom of the reactor, washed, drained and dried before being packaged.

The minimum phosphorus concentration in the effluent for the technical and economic viability of the process is 70 mg/l. It is therefore often necessary to have a biological phosphorus removal on the water line.

key figures

- ROI from 5 to 10 years

- up to 90 % recovery of phosphorus from phosphorus-rich effluents

among references

- Villiers-Saint-Frédérique, France; capacity: 42,000 PE

- Sausheim-Mulhouse, France; capacity: 490,000 EH

- commercialization of struvite as fertilizer generates revenue

- reduction of chemicals consumption for phosphorus physicochemical treatment

- less energy consumed for biological treatment through the removal part t of nitrogen by struvite precipitation)

- increase of equipment service life thanks to controlled and localized precipitation of struvite

- reduction of sludge disposal costs by minimization of sludge volumes

- resource recycling (phosphorus, nitrogen) and contribution to the circular economy

- lower environmental footprint through energy savings, sludge volume reduction, increased equipment service life, reduced chemical consumption

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later