flocculators application

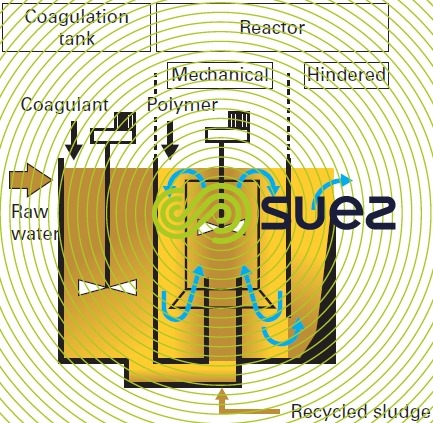

Reading time:An illustration of optimisation: mechanical flocculator coupled with a hindered settling flocculator (figure 6):

In this case, the mechanical flocculator is a high energy reactor used to form small but dense floc. The hindered flocculator is a high flow reactor used to increase floc size. This system constitutes the most progressive flocculator in the degremont® range and is particularly used with the Densadeg.

In this particular application, flocculation is optimum thanks to:

- highly concentrated, adjustable flow rate sludge recirculation;

- in the first reactor, the turbine is enclosed in a sheath that ensures a good water-sludge and water-polymer mix (these being injected beneath the turbine), even mixing throughout the reactor and satisfactory bottom sweep;

- this turbine’s speed of rotation (two to three times higher than that of a normal flocculation turbine); this speed shears the larger, lightweight floc. However, these small fragments of floc are immediately re-agglomerated by injecting polymer, thus reforming a denser flow which explains the high sedimentation rate and the high concentration of sludge extracted from a Densadeg;

- passage through two successive reactors, minimising short circuits;

- the final hindered settling (in effect, two chambers in series, with downward and then upward flow and a decreasing G), producing a medium-size floc that is particularly dense and even in size.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later