the gyrazur, a granular contact mass reactor

Reading time:principle and conditions governing its use

The Gyrazur is a fluidised bed unit typically used to remove carbonates from deep water featuring high levels of calcium and carbonate hardness; in effect, in this case, there are no suspended solids and, therefore, no requirement for concomitant clarification (however, subsequent filtration remains essential).

The main difference with sludge contact precipitation appliances (see sludge recirculation settling tanks and sludge recirculation settling tank – thickener : the densadeg) resides in the use of larger germs. Whereas in the preceding units, the size of elementary calcium carbonate crystals is in the region of 1/100th of a mm, in this case, for crystallisation, we use a mass usually made up of grains of sand initially measuring between 0.2 and 0.4 mm. Calcium carbonate precipitates by crystallising on the surface of the grains between which water percolates upwards at high speed in order to fluidise the grains and to optimise the solidfluid exchange without running the risk of the grains sticking to each other. The extensive surface area available ensures a complete and fast reaction whence the designation of « catalytic carbonate removal » occasionally given to this process, that the other main process (with sludge recirculation) works in the same way.

These systems have three advantages:

- reduced ground coverage (but very tall structures);

- possibility of pressurised operation; when combined with closed filters, they will remove carbonates from water without disrupting hydraulic loading;

- producing, instead of sludge, diameter beads between 1 to 2 mm that drain very fast and can be re-used (industry, agriculture).

As carbonate removal using the Gyrazur consists in the crystallisation of calcium carbonate to produce calcite (rhombohedra) in contact with the crystallisation support mass, any compound that does not precipitate as crystals must be avoided. Therefore, this process cannot be applied to water that contains too much colloid or iron. Additionally, we have to avoid the precipitation of magnesium oxide which reduces the speed at which beads settle or magnesium hydroxide which produces a light floc which will leave the unit.

The Gyrazur is used to provide water from which carbonates have been removed and that contains little suspended solids, these mainly being linked to any impurities in the reagent used.

description

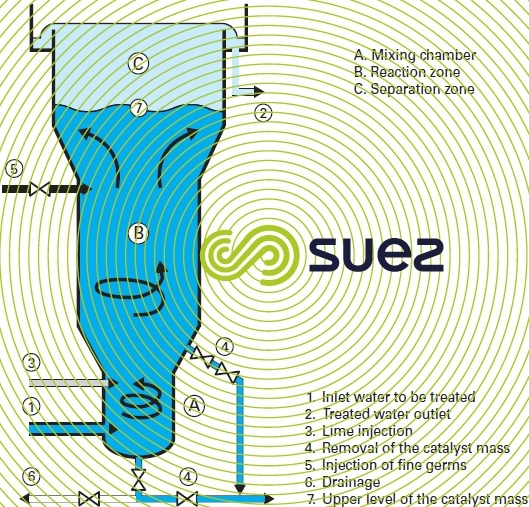

The Gyrazur (figure 24) is a metal appliance that consists of a stack of three cylinders, having a diameter that increases from the base to the top and interconnected by cone frustums:

- the raw water is injected horizontally and tangentially at (1) into the mixing chamber, thus causing this chamber to adopt a rising spiral motion, inducing the coarsest part of the crystallisation support mass to form a suspension. In effect, as in the case of any fluidised bed, this one will grade itself: the small, recently injected germs remain towards the top of the blanket and only the more heavily coated germs will drop down into the lower cylinder from which they are removed from time to time (4);

- the lime (or sodium hydroxide) is injected at (3) into the mixing chamber (vigorously agitated zone ensuring a flash mix) as a very dilute lime slurry or lime water or sodium hydroxide solution;

- the treated water, separated from the crystallisation support mass in the upper cylinder (7) is collected from the top of the appliance and remove through (2);

- as the grains grow continuously, the extraction of the larger grains has to be compensated by injecting fine germs at (5) to replace the ones that have been taken out.

High velocities, ranging from 30 to 90 m · h–1, are feasible in the separation zone. This range of equipment can treat individual flow rates ranging from 50 to 2 000 m3 · h–1. Photo 25 features the upper section of four Gyrazurs responsible for partial carbonate removal, using lime, from water sourced from an eutrophic reservoir, after preclarification through Pulsator clarifiers.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later