coolers

Reading time:Three types of cooler are used to air cool hot water (figure 17 cooling circuits) : wet, dry or hybrids.

In order to design a cooler, we require the following properties :

- the amount of heat to be removed per hour Q (in J · h–1) or cooler power;

- the water flow to be cooled qv (in m3·h–1)

- the difference or drop in water temperature T (in °C) (usually between 8 and 12 °C) from which we can deduce Pr = qv ΔT Cp.

Care must be taken when calculating the cooled water temperature. This temperature must be calculated after asking the following questions :

- what is the maximum cooled water temperature that is compatible with the plant’s satisfactory operation?

- can slightly higher levels be accepted for a limited period of time?

- can this maximum temperature be reached depending on the climactic conditions in the knowledge that the "approach" i.e., the difference between the temperature of the cooled water and that for cold wet air in general between 5 and 6 °C (cf wet cooler) or that of dry air (cf dry cooler), must be at least 5 °C.

«wet» or atmospheric coolers

The water to be cooled is in contact with the air and heat transfer mainly takes place through the partial evaporation of water and through the air becoming enriched with humidity (85 to 90 % of the exchange) and also through direct heating of the air or convection. Therefore, this exchange primarily depends on the humidity in the ambient air.

The classic industrial cooler is achieved as indicated in the section cooling circuits, figure 17.

It can be of the following types :

- natural draught, the air circulates because of its lower density in the tower;

- countercurrent air and water circulation;

- film or drop exchange surface area depending on the nature of the water, (minimum packing volume);

- mechanical draught, the air circulation is driven by a suction fan in classic solutions and by a blower for certain special cases.

Throughout this operation, the air is humidified and heated.

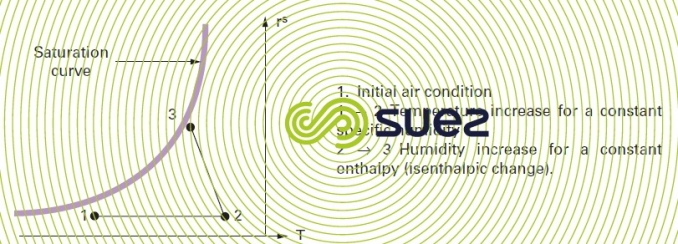

The illustration in the wet air diagram gives us (figure 54) :

Note : it is assumed that the air discharged by the cooler is saturated with water.

If we know the water flow and the T, we can calculate the cooler power (Pr) and, therefore, point 2.

In order to obtain point 3, we only have to follow the isenthalpy passing through 2 until we reach the saturation curve.

where :

H3S specific air enthalpy at point 3 (in KJ·kg–1),

H2S specific air enthalpy at point 2 (in KJ·kg–1),

H1S specific air enthalpy at point 1 (in KJ·kg–1),

mas = dry air flow rate (kg·h–1).

dry coolers

Water circulates in vaned tubes and does not come into contact with the air.

During this operation, calories are transferred by air heating alone.

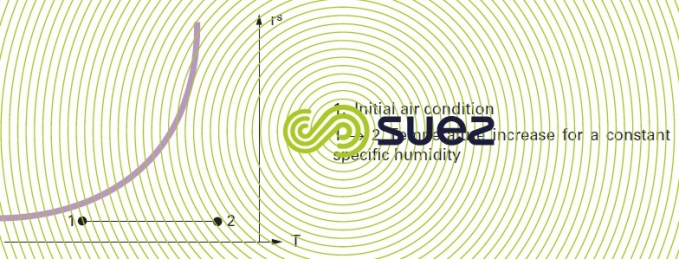

The illustration using the wet air diagram gives us (figure 55) :

If we know the quantity of heat to be removed (or cooler power Pr), we can establish point 2.

dry, humid or hybrid coolers: "plume-free towers"

This technique consists in combining a serie of "dry" type exchangers with "wet" type cross-current or countercurrent cooling.

There are many possible dry zone/wet zone combinations. For examples, let us consider the case where water first travels through exchanger bundles before entering into the wet zone (most of the thermal power being eliminated in this zone).

The air flows exiting both zones are mixed so that the air exiting the system is not saturated with humidity. In this case, the cooler does not deliver a plume of fumes.

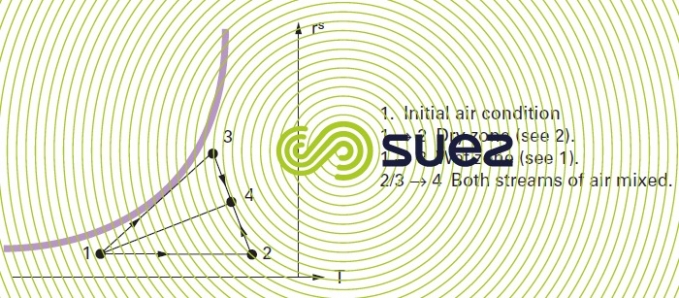

The illustration using the wet air diagram gives us (figure 56) :

Notes :

- 2 and 3 do not constitute an isenthalpy;

- in order to determine 2 and 3, we require data on the cooler used (which is not the case here);

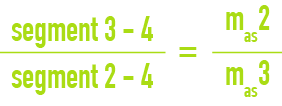

- point 4 is determined graphically by using the following relation :

where :

mas2 = dry air flow crossing through the dry zone,

mas3 = dry air flow crossing through the wet zone.

cooling dirty water

When recirculating gas wash water or when cooling wastewater before purification, coolers can be affected by problems caused by scaling, soiling and even corrosion. These difficulties can be limited by replacing the exchange surface using lines trickling over packing with drops of water sprayed onto plastic gratings.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later