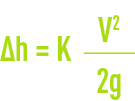

minor losses in the pipelines, fittings, valves… for water

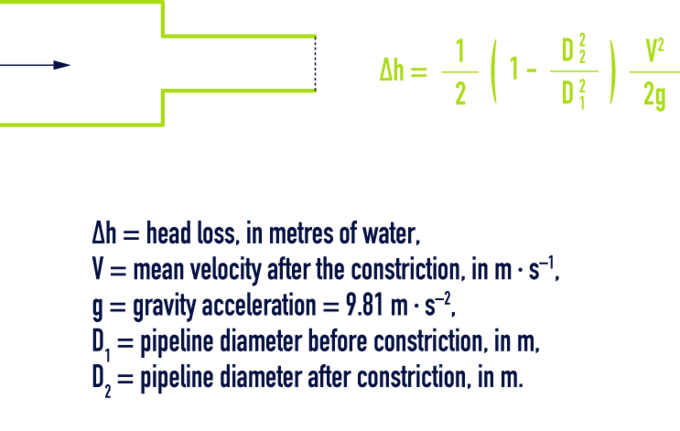

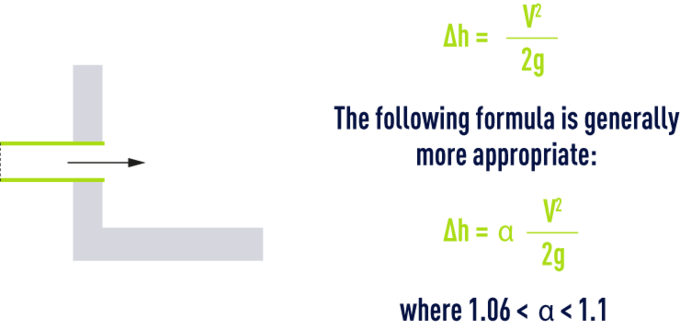

Reading time:sudden constriction

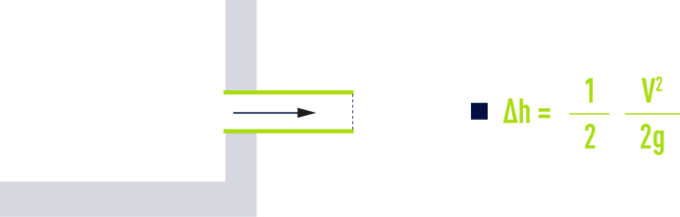

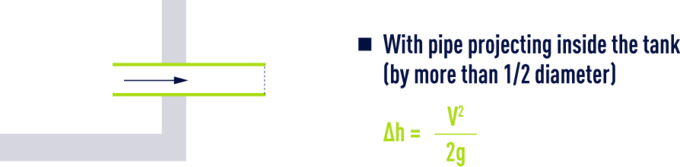

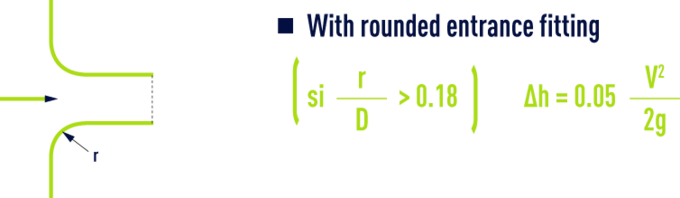

Special case: pipe emerging from a large tank

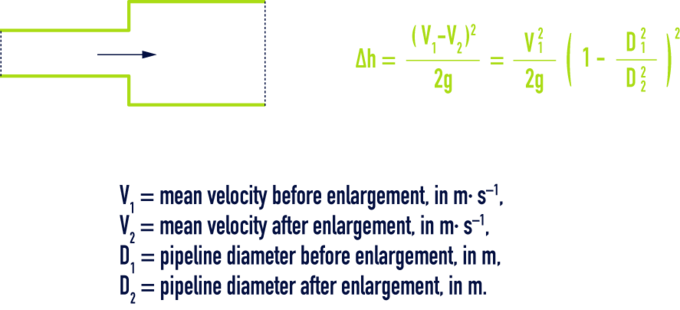

sudden enlargement

Special case: pipe entering into a large tank

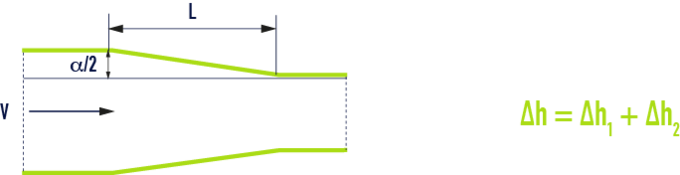

inlet taper

friction loss (∆h1)

Evaluate pressure drop ∆h1', in a cylindrical pipe of the same length and having a section equal to the large section :

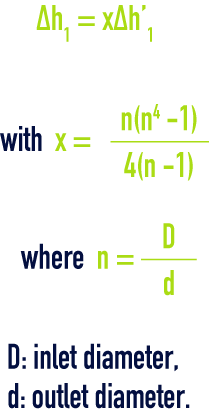

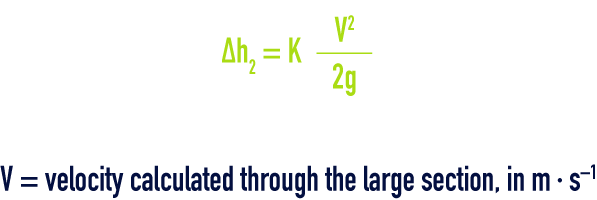

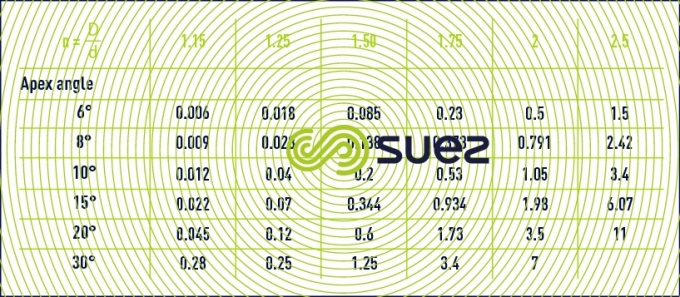

head loss by detachment (∆h2)

Values for K (table 57) :

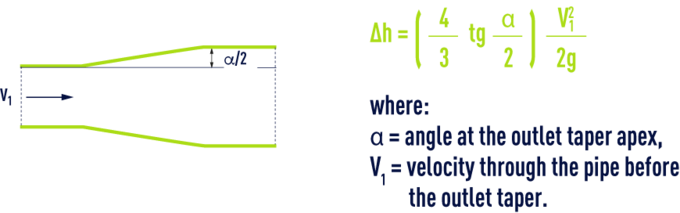

outlet taper

lorenz formula

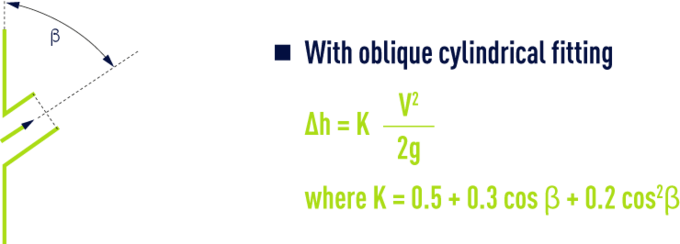

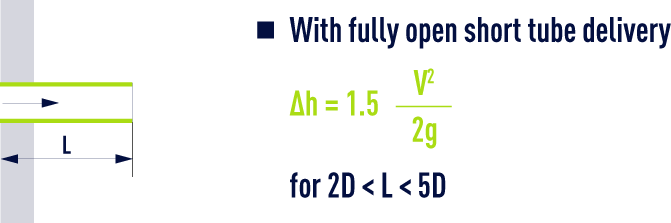

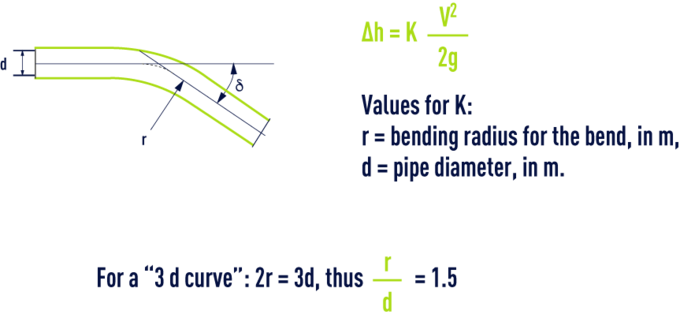

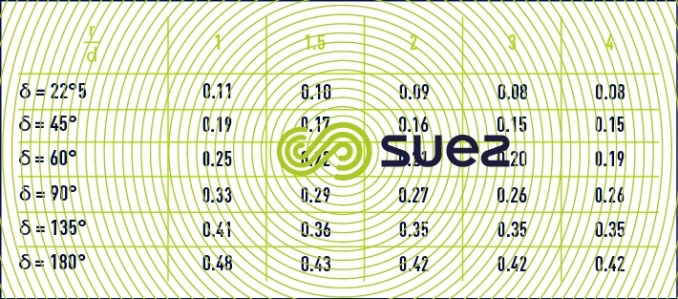

bends

rounded bends

Elbow delivering into a closed tank (K total)

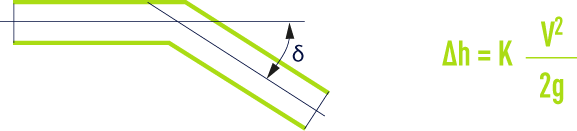

sharp bends :

T components

It is assumed as follows :

- branch pipes have the same diameter as the main pipe;

- couplings have sharp angles.

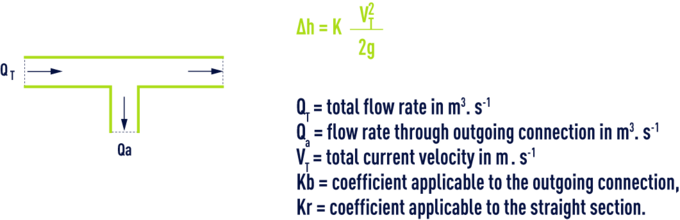

outgoing branch pipe

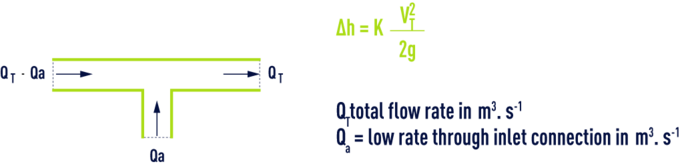

inlet branch pipe

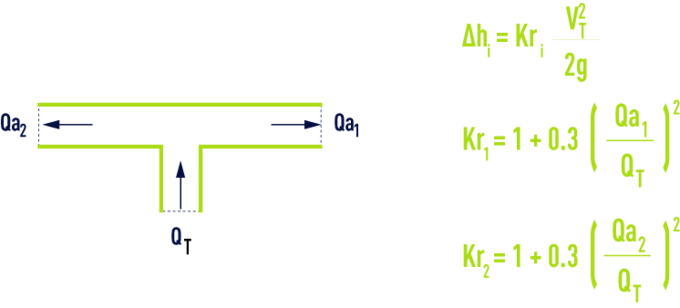

symmetrical T, flow separation: (welded steel T)

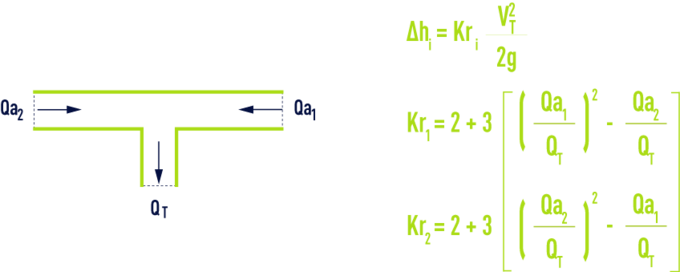

symmetrical T, converging flows

valves and taps

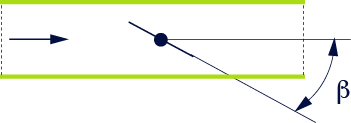

rotating or butterfly valves

The head loss coefficient according on the valve opening angle depends on the hydraulic profile of the butterfly: for guidance, table 63 provides a few typical values; however, it is advisable to refer to manufacturer tables for greater clarification.

gate valve

plug valve

flap valves

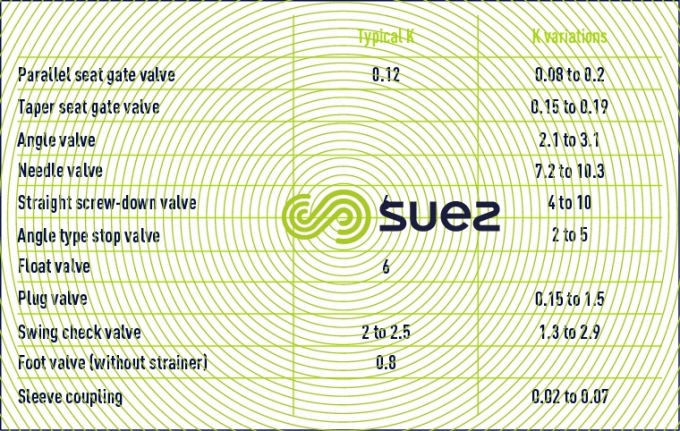

open valves and couplings

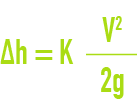

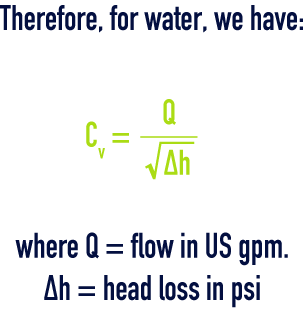

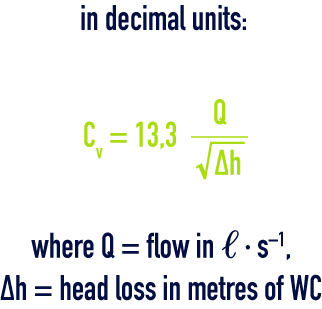

valve coefficient Cv

The normal practice consists in allocating a flow coefficient Cv to the different openings. By definition, Cv is the water flow at 15°C expressed in US gpm that travels through the constricted section for a 1 psi head loss, which is more or less equivalent to the water flow expressed in litres per minute, creating a head loss of 5 mbar or 0.05 m of WC .

Therefore, for water, we have :

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later