coming into line with new water quality standards

Reading time:The steps taken to ensure the compliance of certain water quality parameters are reviewed below.

THM

Replacement of pre-chlorination with pre-ozonation (e.g. Limoges, Metz, Mont Valérien, Orly, France; Pariacabo in Kourou, Guyana; Grafham and Hanningfield, Great Britain) and thorough removal of THM precursors from the system (see below) before final chlorination.

pesticides and other OM problems (including tastes and odours)

Optimising coagulation

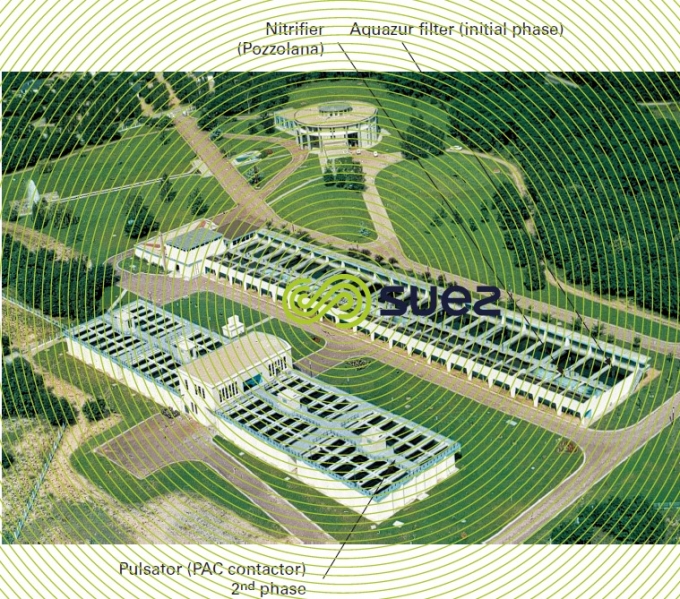

Injecting PAC upstream from the sludge blanket clarifiers (Pulsator) for use as PAC contact medium upstream from the filter battery; at Aubergenville, near Paris, for treating groundwater, clarifiers were built to protect the existing nitrifier and polishing filter batteries (photo 31).

Incorporating the Cristal process (PAC + UF, see section membrane processes) downstream from a clarification system (e.g. Vigneux, France).

Converting sand filters into GAC filters (e.g. Viry-Châtillon and Morsang 1st phase near Paris; Moulle plant in Dunkirk, France; Brno, Czech Republic).

Constructing GAC filters as a second filtration stage, a preferred option to the preceding solution when there is enough space (many such examples in France, England, Italy, etc.).

nitrates

Addition of an ion exchange nitrate removal stage at the end of the system, downstream from clarification (e.g. Kernilis plant in Lesneven, France or Rest plant in Plouenan, France, Vivier plant in Niort, France…).

ammonia

Incorporating a nitrification reactor (e.g. Louveciennes, near Paris, France; Okhla in Delhi, India).

lead (prevention)

Among other problems, lime used to remove carbonates from water containing high levels of calcium carbonate alkalinity, very low pHs, and where the balancing CO2 prevents the formation of the lead hydroxicarbonate protective skin (see examples in the section carbonate removal and/or softening).

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later