sludge processing

Reading time:nature of the sludge

Sludge produced from the treatment of raw water to render it potable comes from the extractions or blowdowns undertaken during sedimentation (or flotation), when this exists, and from filter backwashing as well as, if applicable, clarification membrane backwashing.

The suspended solids contained in this sludge include:

- matter present in the water prior to treatment: plankton, flocculated organic and mineral matter, metal hydroxides from the oxidation of ions present in the raw water (iron, manganese);

- hydroxides from coagulation-flocculation reagents added as part of the treatment process;

- if applicable, adsorbant reagents (PAC), debris detached from GAC filter biological films.

In the case of carbonate removal using lime, these solids will mainly consist of calcium carbonate.

coagulation over filters

The average concentration of suspended solids in filter backwash water can vary from 200 to 1 500 g · m–3. One needs to include a thickener that will produce sludge having a minimum suspended solids content of 20 g · L–1 in order for the sludge to be dewatered. The Densadeg is particularly well-suited to this purpose.

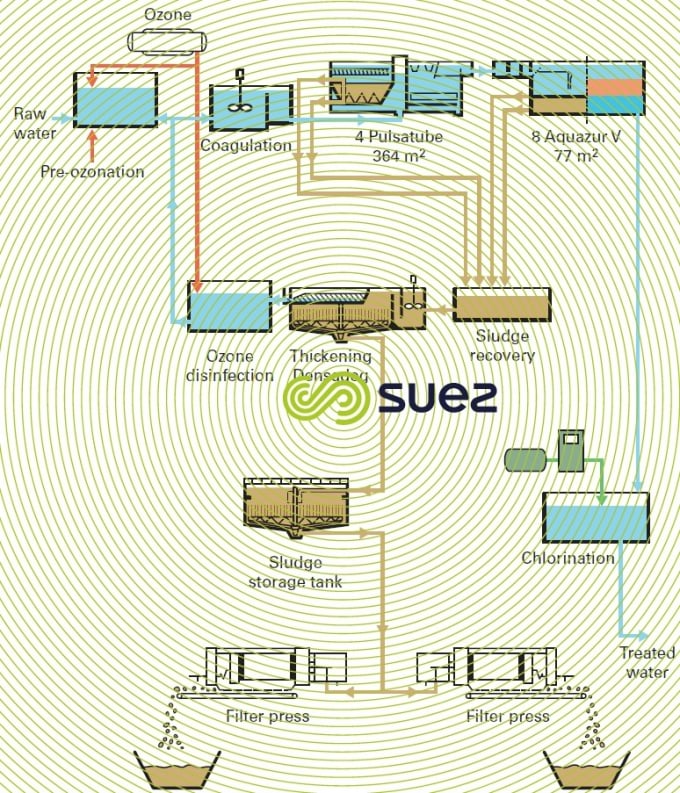

complete treatment

When the clarification system includes coagulation, flocculation, separation (sedimentation or floatation) and filtration, these systems will produce two types of sludge :

- filter backwash water : this water is stored in a tank having a capacity equivalent to the amount of backwash water from one or, even better, two filters. In the past, this water was recirculated to the plant inlet without undergoing any preliminary treatment; at present, this practice is no longer recommended (and may even be banned in some countries); in effect, by dropping pre-chlorination in many plants, this has sometimes led to the uncontrolled development of algae and/or bacteria within filters and in the recycle circuit, potentially resulting in a deterioration of raw water quality. Additionally, when the presence of parasitic protozoan cysts is suspected, these will be effectively screened out by the filters and will be present in the backwash water and will enrich the water to be clarified accordingly. Therefore, they must be eliminated along with the suspended solids before any recirculation takes place. The most common types of equipment used are:

- static thickeners;

- static thickeners with recirculation;

- flotation (e.g. Moulle (France), where there are two separate dissolved air flotation applications, see photo 16);

- the Densadeg (e.g. Tavira, Portugal, figure 19).

- sludge extracted from the separations stage: the amount of this sludge will depend on the nature of the water and on the separation techniques used. On average, it will represent between 0.5 and 2% of the volume processed. If the sludge cannot be routed to the urban sewer system, its treatment in situ must be considered using the thickening and dewatering techniques described in chapter liquid sludge treatment. It should be noted that the Densadeg alone for clarification can avoid the need for a separate thickening stage; while operating at high hydraulic loading (15 to 20 m · h–1), it can be used for the combined treatment of filter backwash water and of sludge extracted from the settling tanks. An example is provided by the Tavira plant (Portugal) (figure 19)

When alum is used as the coagulant, its recovery may be considered in some cases (acidification) although, as a rule, this is not cost-effective.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later