aqueous fluid destruction

Reading time:emulsions

Several techniques are available for use on these fluids which contain hydrocarbons or other products that will not mix with water:

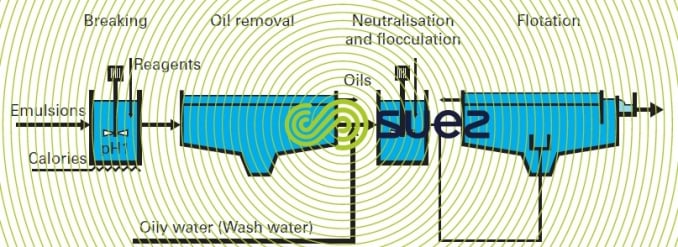

- "hot breaking"(65 to 80 °C) using the acid method (pH 1 to 2) with a mineral coagulation agent (Aℓ or Fe). After a contact time established by trials, the oils are released and separated by natural settling or by centrifugation. Dissolved air flotation can be used for polishing. Should this not be feasible, effluents must be sent to a municipal wastewater treatment plant;

- "cold breaking" with organic de-emulsifying agents. Jar-tests can be used to evaluate the viability of this process and to determine the requisite contact time. The results obtained will be similar to those for hot breaking but this method produces less sludge and, therefore, will frequently be more costeffective when it can be used. Figure 66 provides a viable scheme for both these types of breaking techniques;

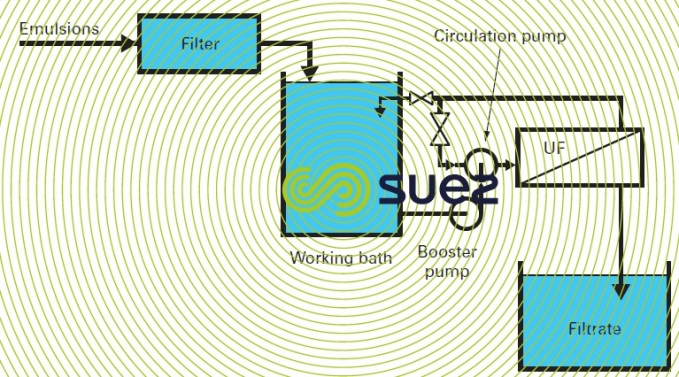

- ultrafiltration : this process avoids the use of reagents and will produce a better quality of treated water. This technique has to be validated by pilot tests that will establish feasibility as well as membrane fouling risks. The concentrate obtained will contain between 30 to 50% of oils that have to be sent for incineration or to an approved destruction center (figure 67);

- evaporation : this process is used to obtain a condensate that is free of suspended solids (but maybe containing oils) but that will still contain some COD (low boiling point products). Therefore, it will have to be sent to a wastewater treatment plant. The paste-like residue containing oils will be sent for incineration. It will contain over 80% oil. This technique will produce an effective treatment but only applies to fairly low waste volumes (5 m3·h–1 maximum).

Note: the removal or free oils beforehand will always be necessary (figure 68).

semi-synthetic fluids

These fluids are low in hydrocarbons and, therefore, the preceding treatments remain applicable; however the COD reduction level will be lower than for emulsions.

These treatments must be followed by supplementary treatments : biological treatment (after dilution if these fluids are toxic).

synthetic fluids

The only possible options are destruction by evaporation and/or by incineration. However, ultrafiltration can be used to remove all spurious free oils (leaks from machine tools, oil contributed by the components), thus considerably extending fluid service life and restricting the frequency with which they are discharged.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later